Shapal (A Machinable Aluminum Nitride Ceramic Material)

Composition and Characteristics of Shapal

Composition: Shapal is mainly composed of aluminum nitride and boron nitride. This mixed structure endows it with unique physical properties.

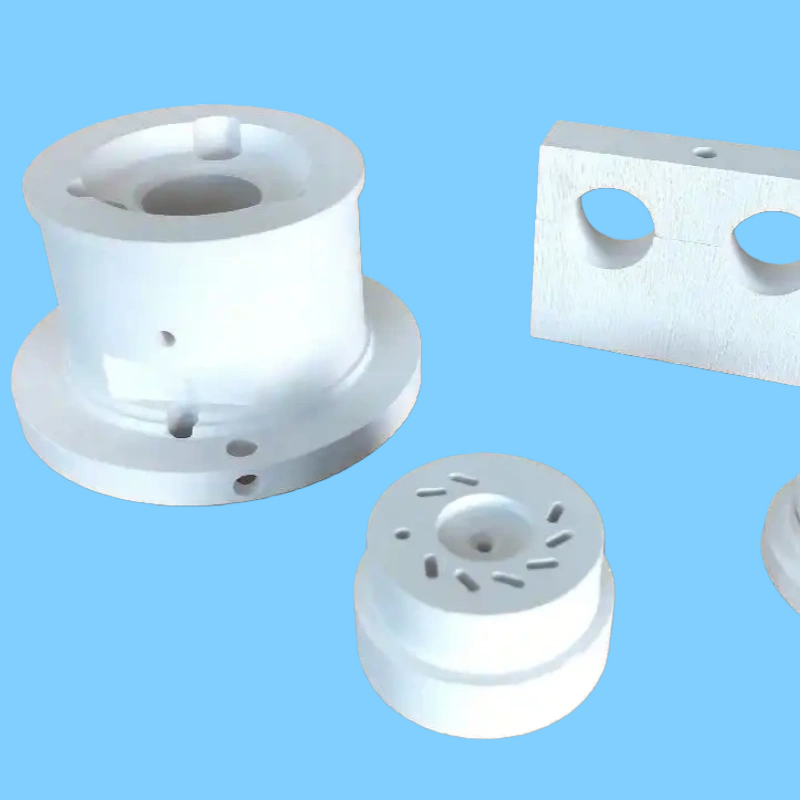

Machinability: Shapal exhibits outstanding machinability and can be processed into high-precision complex shapes through various methods such as drilling, turning, and milling.

Thermal Conductivity: Its thermal conductivity is approximately five times that of aluminum oxide, making it an excellent thermal conductor.

Mechanical Strength: Shapal has a high mechanical strength and flexural strength of 30 kg/mm², which is comparable to that of aluminum oxide.

Electrical Insulation: It features excellent electrical insulation properties, with a low dielectric loss factor and a small dielectric constant.

Coefficient of Thermal Expansion: Its low coefficient of thermal expansion makes it suitable for use in high-temperature and thermal shock environments.

Application Fields of Shapal

Electronic Components: Used in electronic components that require electrical insulation and heat dissipation.

Vacuum Environments: Provides effective sealing under vacuum conditions, making it suitable for vacuum components.

Semiconductor Equipment: Utilized in heat sinks and other components of semiconductor production equipment.

Aerospace: With its high strength and low coefficient of thermal expansion, it is suitable for high-temperature components in the aerospace field.